Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

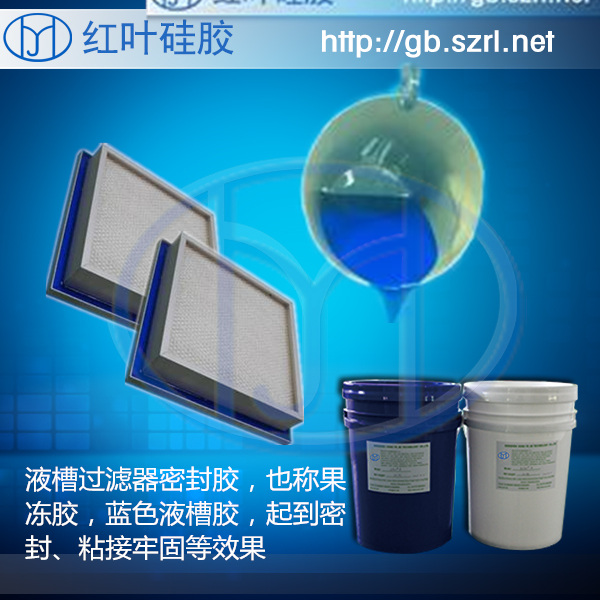

High-efficiency filter tank glue

Category:

Number: 1375406530231947264

Product Description

Liquid tank glue is the abbreviation of a viscous, gel-like two-component addition type liquid tank sealant , which is specially used in high-efficiency air filters. Silica gel components A and B are both liquid liquids. Glue A is transparent, and glue B is blue. It is safe, environmentally friendly, and has high toughness. It can be cured at room temperature or heated for rapid vulcanization. It is a special potting material for air filters. the first choice!

Main uses of high filter tank glue and blue jelly glue :

Liquid tank filter silica gel and liquid tank sealant are mainly used for liquid tank type high-efficiency air filter, optical electronics, LCD liquid crystal manufacturing and sealing of precision electronic components, and play a protective role such as sealing, moisture-proof, shock-proof and insulation. This product has good adhesion to aluminum, galvanized sheet, stainless steel, etc. It is also widely used in plane bonding, sealing and repairing under high temperature conditions , such as special potting glue for air filters, high temperature ovens, high temperature Bonding and sealing of high temperature equipment such as air filters and induction cookers.

Main features of high filter tank glue , blue jelly glue

Excellent chemical stability, safety and environmental protection, high toughness, moderate hardness and good elasticity recovery; excellent weather resistance, corrosion resistance, waterproof, moisture-proof, high temperature and low temperature resistance, no deformation; Stress without cracking, with good self-recovery sealing effect.

1. Low viscosity, good perfusion;

2. It can be cured at room temperature or heated;

3. Good viscosity and softness;

4. Good sealing, no oil after curing;

The use technology of high filter tank glue and blue jelly glue

1. Before mixing, firstly mix components A and B in their respective containers fully and evenly.

2. When mixing, the weight ratio of A component: B component = 1:1 should be observed.

3. After mixing evenly, defoaming at 0.08MPa for 3 minutes.

4. The temperature given in the technical parameter table should be maintained before and after curing when the liquid tank rubber compound is used . The curing speed of the silicone rubber compound is affected by the curing temperature. It can be cured into a gel in 3-8 hours at room temperature. It takes a long time to cure in winter. It is recommended to use heating to cure, 20 minutes at 80 ~ 100 ℃, and about 8 hours at room temperature .

Precautions for high filter tank glue and blue jelly glue

1. The liquid tank rubber material should be sealed and stored. The mixed rubber should be used up at one time to avoid waste.

2. This product is a non-dangerous product, but do not enter it and eyes, if you are not careful, it can be washed with clean water.

3. After being stored for a period of time, the silica gel may be delaminated. Please stir well before use, it will not affect the performance.

4. Contact with the following chemical substances will make the product not solidify. During use, please avoid contact with the following substances.

If you have no previous experience in mold opening, you can log in to our company website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can log in to our company website for inquiries related to silicone application technology , or you can contact our online service staff, or send an email to hyd@szrl.net

The conventional packaging of liquid tank adhesive material manufacturers :

Component A: 20, 200KG/barrel

Component B: 20, 200KG/barrel

Transported as non-dangerous goods, storage period of 1 year, airtight, acid-base and impurity-proof.

National hotline: 189-8878-9544

National hotline: 189-8878-9544

Keywords: