Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

Product Description

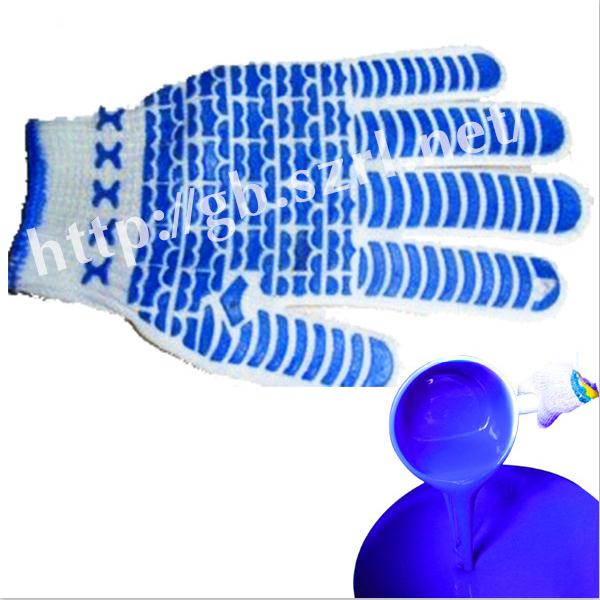

The main purpose of coating silica gel

Coated silicone is especially suitable for coating on floral tapes or underwear and socks for non-slip purposes. High temperature resistant cloth, low temperature resistant cloth, insulating cloth, anti-corrosion cloth, high-grade tent cloth for outdoor use, high-grade umbrella cloth, anti-aging cloth and other fabrics coating processing and anti-slip purposes.

Excellent anti-skid performance, no pollution, moderate hardness, firm adhesive bonding

Wear-resistant, washable, high temperature resistant, high three-dimensional level, excellent texture

Non-slip tape, special label silicone for woven label products (fabric-coated silicone), non-slip floral tablecloth, medical garter

Food grade, non-toxic and tasteless, FDA food grade certification

High transparency, high tensile and tear strength, good bonding effect

Low linear shrinkage ( ≤0.1% ), no low molecules are released during the cross-linking process, so the volume remains unchanged

Coating Silicone Details Parameters

|

model |

TB0330 |

|

Exterior |

translucent |

|

Hardness (Shore A ) |

30 ± 2 |

|

A and B component mixing weight ratio ( A:B ) |

1:1/10:1 |

|

Dynamic Viscosity ( mPa.s ) |

60000 ±10000 |

|

Tensile strength ( MPa ) |

4.6 |

|

Tensile strength ( KN/m ) |

19 ± 2 |

|

Elongation ( % ) |

360 |

|

Operating time ( 25 ℃) |

12-24hrs |

|

Vulcanization time ( 100-120 ℃) |

10-20(mins) |

How to use the coated silica gel : Mix the two components A and B evenly by weight 1:1/10 : 1 , and then operate after vacuum defoaming.

Precautions for coating silicone: Do not touch the container or mold that has been adjusted with condensation type glue during operation . ), alcohols, water contact (especially PVC contains lead and tin, which will poison the catalyst), such as organotin compounds and silicone rubber containing organotin sulfur, sulfide and sulfur-containing rubber, amine compounds and containing Amine materials, otherwise, the addition type liquid silicone will be sticky, will not cure or cure incompletely.

Package:

1. Conventional packaging with A and B ratio of 1:1:

50kg/set (A component 25kg + B component 25kg)

400kg/set (A component 200kg+B component 200kg)

2. Conventional packaging with A and B ratio of 10:1:

22kg/set (A component 20kg + B component 2kg)

220kg/set (A component 200kg + B component 20kg)

If you have no previous experience in mold opening, you can also log in to our website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can log in to our company website Service Center to inquire, you can also contact our online service staff, or you can send an email to hyd@szrl.net

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544

Keywords:

Previous

Next