Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

Silica gel for automobiles and ships

Silica gel for automobiles and ships is a two-component addition type silicone material. It is composed of two components A and B, which are fluid and liquid silicone rubber. It can be cured at room temperature or heated quickly. Excellent high temperature resistance, high tear resistance and non-toxic and tasteless addition type liquid silicone raw material, not limited by the thickness of the product, can be deeply vulcanized, cast and brushed, and the operation is simple and convenient.

Number: 1375406520262086656

Product Description

Silica gel for automobiles and ships is a two-component addition type silicone material. It is composed of two components A and B, which are fluid and liquid silicone rubber. It can be cured at room temperature or heated quickly. Excellent high temperature resistance, high tear resistance and non-toxic and tasteless addition type liquid silicone raw material, not limited by the thickness of the product, can be deeply vulcanized, cast and brushed, and the operation is simple and convenient.

Main uses of silicone products for automobiles and ships:

Provide various types of auto parts mold silica gel , a kind of auto and ship mold silica gel with high transparency silicone, high tear resistance, high and low temperature resistance, addition type silica gel raw material, not limited by product thickness, precision parts mold silica gel , automotive zero Parts mold silicone products , mainly used for automotive tire molds, automotive silicone tires, yacht gel coats, alloy vehicles and various high-quality mold casting handicrafts and other silicone mold production.

Performance characteristics of silicone products for automobiles and ships:

·It is not limited by the thickness of the product, and can be deeply cured;

·Excellent chemical corrosion resistance, high and low temperature resistance can reach -50~250 degrees;

Low linear shrinkage (≤0.1%), no low molecules are released during the cross-linking process, so the volume remains unchanged;

·High tensile and tear resistance strength, many times of overturning;

·Good fluidity, easy to pour; it can be cured at room temperature or heated, and it is easy to operate.

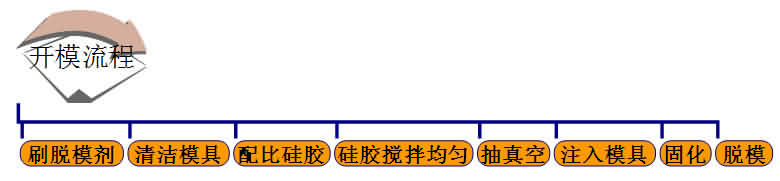

Instructions on the operation method and mold opening process of silicone material for automobile and ship special molds :

1. Mixing: Component A (base glue) and component B (curing agent) are mixed in a weight ratio of 1:1. The mixing can be done manually or by using equipment.

2. Deaeration: The mixed silicone rubber compound for automobile and ship molds should be deaerated before filling the mold. When a small amount is used, it can be carried out in a vacuum dryer. Under vacuum, the volume of the rubber compound will foam and increase by 4 to 5 times. Therefore, the volume of the defoamed container should be 4 to 5 times larger than the volume of the rubber compound. After a few minutes The glue volume returns to normal, and the defoaming process is completed when no bubbles escape from the surface (about 10 minutes).

3. Surface treatment: The surface of the mold to be contacted by the rubber compound or the surface of the material to be potted can be used as a release agent such as liquid paraffin.

4. Vulcanization and demoulding: After mixing and defoaming, the silicone rubber for automobile and ship molds is cured at 120±5℃ for 30 minutes, and cured at 60-70℃ for 2-3 hours. The curing time at room temperature is 8-12 hours. The temperature and time can be determined according to the process conditions.

Precautions during operation:

1. When operating, it should be separated from the container that has used condensed silica gel, and use the room temperature silica gel tool to operate this silica gel.

2. Viscosity, operating time and hardness after curing can be adjusted according to customer needs.

This product is a platinum catalyst. Water, impurities, organic tin catalyst, acid, alkali and other organic substances containing sulfur, phosphorus and nitrogen can affect the curing of the glue. Do not mix or contact these substances during use.

If you have no previous experience in mold opening, you can log in to our company website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can log in to our company website service center to inquire, you can also contact our online service staff, or you can send an email to hyd@szrl.net

Conventional packaging and storage of silicone manufacturers:

A component: 20KG/200KG

B component: 20KG/200KG

Transported as non-dangerous goods, storage period of 1 year, airtight, acid-base and impurity-proof.

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544

Keywords:

Previous