Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

Military products silicone

A high-elasticity silicone polymer special- purpose silicone for military industry , which is composed of liquid silicone rubber with two components A and B , which is fluid. It is a kind of two-component addition type liquid silicone rubber. Excellent high and low temperature resistance, high tear resistance, fatigue resistance and non-toxic and tasteless addition type liquid silicone raw material, not limited by the thickness of the product, can be deeply vulcanized, cast and brushed, and the operation is simple and convenient.

Category:

Number: 1375406517405765632

Product Description

A high-elasticity silicone polymer special- purpose silicone for military industry , which is composed of liquid silicone rubber with two components A and B , which is fluid. It is a kind of two-component addition type liquid silicone rubber. Excellent high and low temperature resistance, high tear resistance, fatigue resistance and non-toxic and tasteless addition type liquid silicone raw material, not limited by the thickness of the product, can be deeply vulcanized, cast and brushed, and the operation is simple and convenient.

The main uses of military products silicone material products:

This product belongs to a two-component addition type silicone material, which is processed by mature scientific formula and skilled craftsmanship. Not limited by the thickness of the product, we provide various types of military silicone raw materials and military equipment silicone raw materials , which are widely used in the production of military materials, military product molds, special military product molds, military-grade kitchen supplies, explosion-proof products and other silicone material molds.

The main performance characteristics of silicone materials for military products:

·It is not limited by the thickness of the product, and can be deeply cured;

·Excellent chemical corrosion resistance, high and low temperature resistance can reach -50~250 degrees;

Low linear shrinkage (≤0.1%), no low molecules are released during the cross-linking process, so the volume remains unchanged;

·High tensile and tear resistance strength, many times of overturning;

·Good fluidity, easy to pour; it can be cured at room temperature or heated, and it is easy to operate.

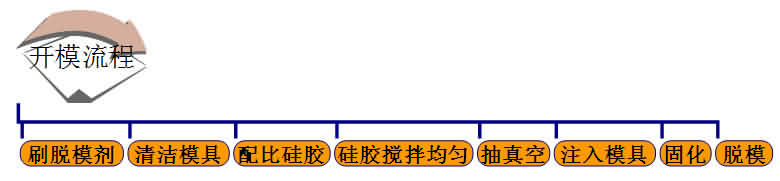

Instructions on the operation method and mold opening process of silicone material for military product molds :

Mix components A and B evenly at a ratio of 1:1, and pour them after vacuum defoaming. The operating time depends on the temperature (0.5-3)H, the curing time (room temperature) is 8-12H, and the temperature is 80-120° C can be cured in tens of minutes. The room temperature quick-drying operation time is less than 20 minutes, and the curing time is 1 hour.

Precautions during operation:

1. When operating , it should be separated from the container that has used condensed silica gel, and the silica gel should be operated with tools that have not used room temperature vulcanized liquid silicone rubber material.

2. Viscosity , operating time and hardness after curing can be adjusted according to customer needs.

This product is a platinum catalyst. Water, impurities, organic tin catalyst, acid, alkali and other organic substances containing sulfur, phosphorus and nitrogen can affect the curing of the glue. Do not mix or contact these substances during use.

If you have no previous experience in mold opening, you can log in to our company website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can log in to our company website for inquiries related to silicone application technology , or you can contact our online service staff, or send an email to hyd@szrl.net

Conventional packaging and storage of silicone manufacturers:

Component A : 20KG/200KG Component

B : 20KG/200KG

Transported as non-dangerous goods, storage period of 1 year, airtight, acid-base and impurity-proof.

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544

Keywords:

Previous