Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

GRC mold silicone

Category:

Number: 1375406502675369984

Product Description

Basic introduction of GRC mold silicone rubber :

GRC mold silicone rubber is a kind of two-component silicone rubber , and it is also a kind of liquid silicone rubber. It consists of two kinds. Component A is a flowable liquid glue, and component B is a curing agent (vulcanizing agent), which can be quickly formed after mixing. Whether it is condensation-type silicone or addition-type silicone, both are suitable for mass production and mold-turning of GRC products. The former is industrial-grade silicone with a ratio of 100:5; the latter is food-grade silicone with a ratio of 1:1 and 10:1. kind.

Application fields of GRC mold silicone rubber :

GRC is suitable for all kinds of building products, batch duplication of decoration products, mainly used for various European-style components, gypsum lines , gypsum waistlines , architectural decoration, background walls, cultural stones, Roman columns, figure statues, garden cement sculptures, Silicone molds for statues, reefs, weathered stones, slate and other products.

Application requirements of GRC mold silicone rubber:

① The pattern is clear, the texture is delicate, and the simulation effect is good, especially in the artificial art stone mold.

②The smaller the shrinkage rate, the better, to avoid product scrap;

③ The tear strength and tensile force are better, and the silicone mold made cannot be deformed;

④ The number of times of mold turning is more, the longer the service life, the better, and it is resistant to acid and alkali and aging.

⑤ To have good operating performance, easy to operate, save time and labor;

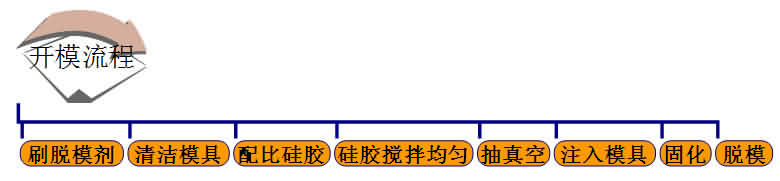

GRC mold silicone rubber operation method description:

According to the different operation methods , there are three kinds of mold opening methods: package mold, brush mold (segment mold, three-dimensional mold, flat mold), perfusion mold.

(Note: The company's products do not advocate adding silicone oil, special soft silicone molds or complex patterns and precision small, you can add 5%-10% silicone oil to adjust the softness of the silicone mold for demoulding.)

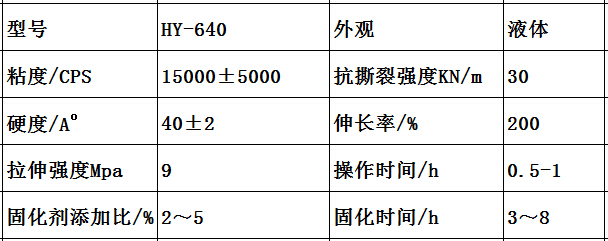

Hongye silicone - GRC mold silicone rubber HY-640 main technical performance parameters:

Remarks : The above parameters are only the parameters of this model HY-640, and the parameters of other models are not shown; if you have special needs, please contact our company; after curing, the hardness, viscosity, and operating time can be specially adjusted and provided according to customer needs.

Precautions for GRC mold silicone rubber :

1. The amount of curing agent should be determined according to the temperature, and it should be reduced if the temperature is high. If the curing agent is used too much, the silicone mold will become hard and brittle; if the curing agent is used too little, the operation time will be prolonged.

2. In order for your silicone mold to achieve the best use effect, please store the mold for at least 24 hours before use.

If you have no previous experience in mold opening, you can also log in to our website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can contact our online service staff or send an email to hyd@szrl.net

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544

Keywords: