Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

soap mold silicone

Category:

Number: 1375406494106406912

Product Description

Introduction of soap mold glue:

Soap mold silicone is a kind of liquid mold glue, which is composed of two components, A and B, which are fluid and liquid silicone. It can be cured at room temperature or quickly cured by heating. The ratio of condensation type liquid glue is 100:5, and the ratio of addition type liquid glue is 1:1 or 10:1. Both kinds of silicone are suitable for making soap molds.

The main purpose of soap mold glue : It is the one with better fluidity in RTV-2 mold silicone, which is very suitable for the operation of pouring molds of soap, soap and handmade soap molds;

It is also very suitable for simulation handicrafts of precision pattern products , toy gifts, polly handicrafts, resin handicrafts, decorations, furniture decorations, garden decorations, garden sculptures, garden simulation animals and plants and other handicraft industries.

Soap mold glue application features:

1. Not limited by the thickness of the product, it can be deeply cured;

2. High-quality mold silicone with excellent fluidity, high temperature resistance and thermal stability is very suitable for perfusion mold operation, but with special reagents, it can be turned into brush mold operation;

3. It has excellent chemical corrosion resistance, and its high and low temperature resistance can reach -50~250 degrees;

4. Low linear shrinkage (addition type liquid glue ≤ 0.1%, condensation type liquid glue ≤ 0.3%), no low molecules are released during the cross-linking process, so the volume remains unchanged;

5. High tensile and tear resistance strength, the silicone mold made will not be deformed for a long time, and the number of mold turning is high, which can be thousands of times;

6. It can be cured at room temperature or heated, and it is easy to operate;

7. The hardness, viscosity, color, operating time and curing time of silica gel can be adjusted according to customer's requirements.

How to use soap mold glue :

If you buy an addition type liquid glue, mix components A and B evenly at a ratio of 1:1, and if it is a condensation type liquid glue, mix components A and B at a ratio of 100:5 (please confirm with the manufacturer) , After vacuum defoaming, it can be poured. The operating time depends on the temperature (20-60 minutes), the curing time (room temperature) is 2-3 hours, and it can be cured within tens of minutes by heating at 80-120 °C.

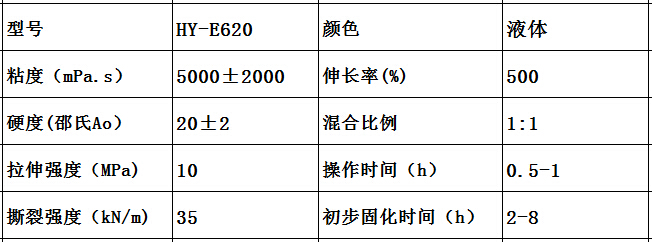

Hongye silicone - mold glue HY-E620 performance parameters:

Remarks : The above parameters are only the parameters of this model HY-E620, and the parameters of other models are not shown; if you have special requirements, please contact our company; after curing, the hardness, viscosity, and operating time can be specially adjusted and provided according to customer needs.

Precautions for soap mold silicone :

1. If you buy an addition type of silicone, please try not to smoke when operating this type of silicone to avoid the silicone not curing or curing unevenly;

2. The HY-E620 introduced this time is an addition type liquid silica gel. The curing agent is platinum catalyst. Water, impurities, organic tin catalyst, acid, alkali and other organic compounds containing sulfur, phosphorus and nitrogen can affect the curing of the glue. Do not mix or come into contact with these substances.

3. No matter whether you buy a condensation type silicone rubber or an addition type silicone rubber, please cure the silicone mold for 24 hours before putting the mold into production, which can effectively prolong the service life of the silicone mold.

If you have no previous experience in mold opening, you can log in to our company website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can contact our online service staff or send an email to hyd@szrl.net

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544

Keywords:

Previous