Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

Resin Sculpture Mold Silicone

Category:

Number: 1375406486590214144

Product Description

Basic introduction of silicone resin sculpture mold :

Resin sculpture mold silicone, including condensation mold silicone and addition mold silicone, the former is traditional industrial-grade silicone with a ratio of 100:5, the latter is a popular addition-type silicone in recent years, also called food-grade silicone , environmentally friendly, non-toxic and tasteless, the ratio is 1:1 and 10:1, 1:1 silica gel is used more.

For the mold making of resin sculpture, brush mold silica gel is used more, mainly because resin sculpture products are generally larger in size, and the patterns are very fine and complex. The vein is copied;

For some resin sculpture products with relatively simple patterns, it is better to use mold-filling silicone. First, the product lines can be reproduced better, secondly, it can save operation time, and thirdly, it can also save labor costs.

Therefore, you can choose the appropriate resin sculpture mold silicone according to the actual situation of your own products .

Resin sculpture mold silicone application :

Resin sculpture mold silicone is mainly used for various large, medium and small pieces of resin model craft pendant, handicraft sculpture, animal clay sculpture mold, fine glass fiber reinforced plastic sculpture , character sculpture, animation game character model customization, traditional plaster statue, Guanyin plaster statue mold, clay sculpture Silicone molds for models, animal clay molds, fiberglass sculptures, government building models and other products. It is also often used in the mold manufacturing of fine products such as film and television prop models, car models, and military gift models.

Application characteristics of resin sculpture mold glue :

①It has excellent fire resistance, and the high temperature resistance can generally reach 180℃-250℃. After adding special materials, it can reach 300℃, which can effectively solve the problem of burning out the silicone mold caused by the heat release of the resin product during the curing process;

②It does not emit oil, which is the leader in the silica gel of the same industry. It solves the problem that oil often occurs in the process of silicone mold overmolding resin products, and prolongs the service life of silica gel;

③The hardness, viscosity and operation time of silica gel can be produced according to customer needs, and the silica gel can be customized for you;

④The shrinkage rate is smaller than that of the peers, the silicone mold made is more durable, and the number of mold turning is high, which effectively saves the production cost;

⑤ The ability to resist tearing and stretching is good, and the silicone mold made is more durable and does not deform;

Instructions for use of resin sculpture mold silicone :

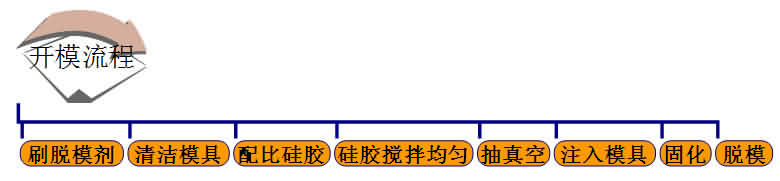

According to the different operation methods , there are three kinds of mold opening methods: bag mold, brush mold (slice mold, three-dimensional mold, flat mold), perfusion mold.

(Note: The company's products do not advocate adding silicone oil, special soft silicone molds or complex patterns and precision small, you can add 5%-10% silicone oil to adjust the softness of the silicone mold for demoulding.)

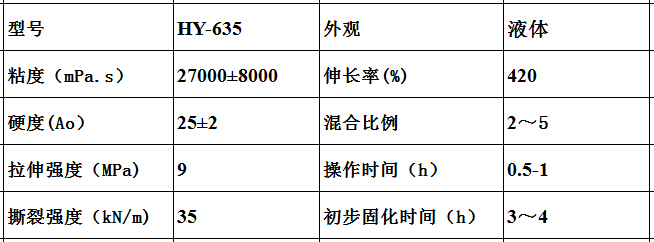

Hongye silicone - no oil mold silicone HY-635 parameters:

Remarks : The above parameters are only the parameters of this model HY-635, and the parameters of other models are not shown; if you have special needs, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted and provided according to customer needs

For the reaction of the ratio of silica gel and curing agent, please refer to:

1. When the amount of curing agent is 1%, the colloid will still flow in 2.5 hours, and it can be demolded in 6-8 hours.

2. When the amount of curing agent is 2%, the colloid will still flow in 50 minutes to 1 hour, and it can be demolded in 2 to 3 hours.

3. When the amount of curing agent is 3%, the colloid will still flow in 28-30 minutes, and it can be demolded in 1.5-2 hours.

4. When the amount of curing agent is 4%, the colloid will flow in 10-15 minutes, and it can be demolded in 1-1.5 hours.

If you have no previous experience in mold opening, you can also log in to our website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can contact our online service staff or send an email to hyd@szrl.net

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544

Keywords: