Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

High temperature resin mold silicone

Category:

Number: 1375406488054026240

Product Description

Introduction of temperature-resistant resin mold silicone :

Temperature-resistant resin mold silicone is a liquid silicone rubber with special materials added to achieve high-temperature resistance. The temperature resistance of Hongyejie mold silicone is generally 180°C-250°C. ℃ above. This section is called RTV-2 room temperature vulcanized silicone rubber, also known as room temperature curing silicone rubber.

High temperature resistant resin mold silicone application:

High temperature resistant resin mold silicone is mainly used for making silicone molds for craft gifts such as POLYSTER, epoxy resin (EPOXY), Pu resin, etc., so as to achieve the role of mass production of resin products and molding. Whether it is a resin handicraft with a fine pattern, or a resin product with a simple pattern, or a resin handicraft with a larger size, or a small handicraft with a small size, this high temperature resistant resin mold silicone is suitable for turning over the mold.

Application characteristics of high temperature resistant resin mold silicone :

1. Excellent high temperature resistance, especially suitable for mold turning of resin products, which solves the problem that resin products release a lot of heat during the curing process, thereby burning out the silicone mold;

2. Thanks to the excellent performance of high temperature resistance, the silicone mold made of this type of silicone has better burning resistance and higher mold turning times, which greatly saves the production cost of unsaturated resin handicrafts;

3. The viscosity, fluidity, operation time, curing time, and hardness and color of the cured silicone rubber before curing can be adjusted according to the customer's requirements, and the silicone rubber can be customized for you;

4. It can be poured or painted, easy to debubble, high and low temperature resistance, aging resistance, no swelling, good tensile force and high tear strength;

5. Good weather resistance, acid and alkali resistance, low linear shrinkage (condensed silica gel ≤ 0.3%, addition silica gel ≤ 0.1%).

Instructions for use of high temperature resin mold silicone :

If you want to split the mold, you must use high-hardness silicone as the mold; on the contrary, for complex patterns and fine and tiny molds, such as filling molds, you need to use soft silicone as the mold;

The amount of curing agent added can be determined according to the actual requirements of customers. If you want to cure quickly, you must add a corresponding amount of curing agent; on the contrary, if you want to cure more slowly, you must reduce the amount of curing agent added accordingly.

(Note: The company's products do not advocate adding silicone oil, special soft silicone molds or complex patterns and precision small, you can add 5%-10% silicone oil to adjust the softness of the silicone mold for demoulding.)

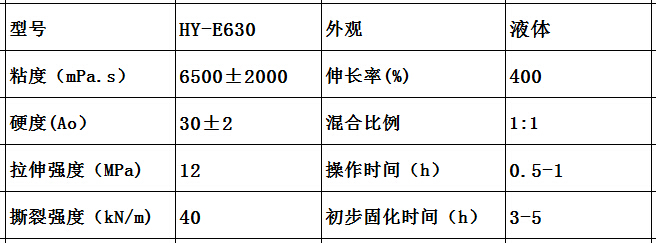

Hongye silica gel - high temperature resistant resin mold silica gel HY-E630 Parameters:

Remarks : The above parameters are only the parameters of this model HY-E630, and the parameters of other models are not shown; if you have special requirements, please contact our company; after curing, the hardness, viscosity, and operating time can be specially adjusted and provided according to customer needs.

Selection guide for high temperature mold silicone :

1. For products with a size of 10-20 cm, the markings are very precise, and low-hardness silica gel should be used for the filling operation.

2. For products with a size of 30-50 cm, use 20-30 degree silica gel for precise markings, and brush mold operation

3. The size is more than 60 cm, and the pattern is not very precise. We recommend using a 40-50 degree silicone brush mold for operation.

If you have no previous experience in mold opening, you can also log in to our website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can contact our online service staff or send an email to hyd@szrl.net

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544

Keywords:

Previous