Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

Cement products mold glue

Category:

Number: 1375406505804320768

Product Description

Brief description of silicone mold for cement products :

Cement product mold silicone is actually a kind of liquid mold glue. It is a high-strength liquid mold silicone rubber specially developed for the mass production of cement products. A silica gel developed mainly based on the characteristics of heavier cement products, easy damage to the mold, and finer patterns and finer lines, which solves the problem that other hard mold materials cannot replicate the pattern design on the cement surface.

Addition mold silicone and condensation mold silicone can both be used for large-scale replication of cement products.

Application areas of silicone mold for cement products :

It is especially suitable for the production of silicone molds for large-scale stone, gypsum, cement components, cultural stones, background walls, sandstone carvings and other products. According to the advantages of Hongye brand cement mold silicone, the patterns of the above products can be perfectly copied and turned over. High number of molds, aging resistance, tear resistance. Thus saving production costs.

The main application characteristics of silicone mold for cement products :

1. In addition to a series of advantages of condensed silicone rubber, Hongyejie’s addition mold silicone rubber has lower linear shrinkage and lower viscosity, and has better fluidity;

2. Because no low-molecular by-products are released during vulcanization, the vulcanization is synchronized from top to bottom and from inside to outside, which can be deeply vulcanized. Under high temperature), the phenomenon that the mold is revisited and degraded

3. High-strength tear resistance, high mold turning times, and good copying effect .

4. The silicone mold made is resistant to aging for a long time, acid and alkali resistance, no deformation, and can be reused many times.

Instructions for the use of silica gel for cement product molds :

Step 1: Mix the silicone glue with the curing agent in proportion and stir evenly

The ratio of silica gel to curing agent is 100:5, 1:1 and 10:1, please confirm with the manufacturer before operation.

Step 2: Vacuum the liquid silica gel to remove air bubbles

The vacuuming time should not be too long. Under normal conditions, it should not exceed ten minutes. If the vacuuming time is too long, the silica gel will be solidified immediately, resulting in cross-linking reaction, making the silica gel curing unevenly, thus causing the mold to be scrapped.

If there is no vacuum machine, it is recommended to buy liquid silica gel with lower viscosity and longer operation time, so that the silica gel can fully discharge the air bubbles by itself.

The third step: processing and production of the outer mold

Pour the evacuated silica gel on top of the product by brushing or pouring . Generally, the method and material used are to close the mold and enclose it with plastic board or wooden board. Once the mold cabinet is filled with plaster, it is enough. Glass fiber cloth, then brush and paste, repeat two or three layers to end the mold outer mold.

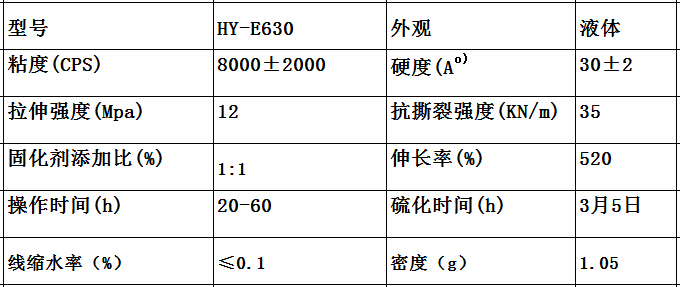

Main technical performance parameters of Hongye silica gel - cement product mold silica gel HY-E630:

Remarks : The above parameters are only the parameters of this model HY-E630, and the parameters of other models are not shown; if you have special requirements, please contact our company; after curing, the hardness, viscosity, and operating time can be specially adjusted and provided according to customer needs.

Selection method of silica gel for cement product mold :

1. For products with a size of 10-20 cm, the markings are very precise and detailed. It is recommended to use low-hardness liquid silica gel for mold filling operation.

2. For products with a size of 30-50 cm, the markings are precise and detailed, it is recommended to use 30-35 degrees of silica gel for the brushing operation.

3. For products with a size of 30-50 cm, the spot is simple and the thickness is very thin, it is recommended to use 25-30 degrees of silica gel for the filling operation.

4. Products with a size of more than 60 cm, regardless of whether the markings are fine or not, generally use 40-50 degrees of silica gel for brushing operation; unless the thickness of the product is relatively thin, the filling operation can be used.

Cement product mold silicone precautions:

1. The amount of curing agent should be determined according to the temperature, and it should be reduced if the temperature is high. If the curing agent is used too much, the silicone mold will become hard and brittle; if the curing agent is used too little, the operation time will be prolonged.

2. In order to achieve the best use effect of your silicone mold, please store the mold for at least 24 hours before use.

If you have no previous experience in mold opening, you can also log in to our website to view detailed silicone mold opening video tutorials .

If you encounter other problems that cannot be solved, you can contact our online service staff or send an email to hyd@szrl.net

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544

Keywords: