Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

Roman Column Mold Silicone Rubber

Category:

Number: 1375406499793883136

Product Description

The basic introduction of Roman column mold silicone :

Roman column mold silicone, that is, mold silicone rubber specially used for Roman column mold, that is, liquid silicone specially used for Roman column mold production . According to the characteristics of the large size of the Roman column and the heavier product, Hongyejie specially has a silicone mold suitable for the Roman column. Component A is a flowable liquid glue, and component B is a curing agent (vulcanizing agent). After mixing the two, it can be quickly formed and the operation is simple.

Application fields of Roman column mold silicone :

Silica gel for cement Roman column mold can be mainly used in the mold making of large decorative building materials products, such as: Roman columns, reliefs, gypsum products, cultural stones, background walls, magnesia products, cement products, imitation jade products and other architectural decoration (Rome columns, cultural stones, mosaics, railings, ceilings, pedestals, fountains, fireplaces, wall decorations, planting utensils, European-style carvings, square landmark sculptures, etc.), and furniture carvings, furniture accessories, furniture decoration and other industry products Silicone mold making.

Performance characteristics of silica gel for cement Roman column mold :

(1) Roman column mold silica gel has excellent fluidity, operability, non-deformation, high temperature resistance, high tear strength, reusable, suitable for fine, fine or messy patterned building materials decoration products, and easier to demould ;

(2) Good weather resistance, high and low temperature resistance, acid and alkali resistance, and aging resistance;

(3) High tensile and tear strength , low linear shrinkage (condensed silicone ≤ 0.3%, addition type silicone ≤ 0.1%);

(4) There are many times of mold turning (for example, the number of copies of gypsum products can reach more than 1,000 times);

(5) Specially adjusted production according to customer product requirements, and can be quickly cured at room temperature;

(6) Good fluidity, easy defoaming, easy pouring, simple operation and easy demoulding.

How to use silica gel for cement Roman column mold :

There are three ways to open the silicone mold: overmolding, rinsing, and perfusion.

How to make cement Roman column silicone mold :

1. The operation method of filling mold or filling mold: filling mold or filling mold is used for relatively smooth or simple products. There is no mold line to save labor and time, that is, the product or model to be copied, surrounded by plastic or glass plates Get up, pour the vacuumed silica gel directly on top of the product, and after the silica gel is dried and formed, take out the product, and the mold can be formed (Note: The infusion mold is generally made of silica gel with a softer hardness, so that it is easier to demould. will damage the product inside the silicone mold).

2. Operation method of sliced mold or sliced mold: apply the vacuumed silica gel to the construction by brushing or perfusion. The sheet mold or slicing mold adopts the brushing method. Before painting, the product or model to be copied is painted with a layer of release agent or release agent, and then the silicone is painted on the product (Note: Be sure to paint Evenly) After waiting for 30 minutes, paste a layer of gauze or glass fiber weft cloth on the surface to increase the strength, then apply a layer of silica gel, and then paste a layer of gauze fiber weft cloth, so that it is almost the same after two times, and the outer mold can be used For materials such as gypsum or resin, only in this way, the service life of the opened silicone mold and the number of times of overturning are relatively much longer, which can save costs and improve efficiency.

(Note: The product or model to be copied before pouring silica gel must be released with release agent or release agent)

3. Production of silicone outer mold : The general method and material used are to surround the mold with rubber boards or wooden boards. Generally, gypsum is used to fill the mold. The other method is to use resin brushing. A layer of resin is pasted with a layer of glass fiber cloth, then brushed and pasted, and the outer mold of the mold can be completed by repeating two or three layers.

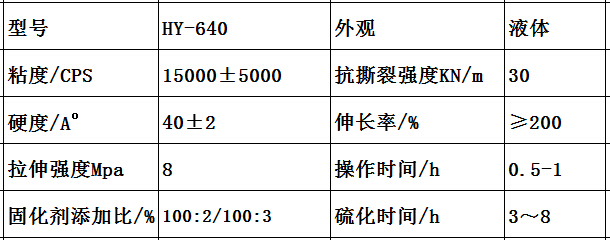

Hongye silica gel - cement Roman column mold silica gel HY-640 Parameters:

Remarks : The above parameters are only the parameters of this model HY-640, and the parameters of other models are not shown; if you have special needs, please contact our company; after curing, the hardness, viscosity, and operating time can be specially adjusted according to customer needs.

Roman column mold silicone precautions:

1. The amount of curing agent should be determined according to the temperature, and it will be reduced when the temperature is high. If the curing agent is used too much, the mold will become hard and brittle; if the curing agent is used too little, the operation time will be prolonged.

2. In order to prevent the physical properties of silicone from changing, it is recommended not to add silicone oil.

3. In order to achieve the best use effect of your mold, please store the silicone mold for at least 24 hours before use.

Hongye silica gel factory conventional packaging:

Commonly used packages for component A are: 25kg/drum, 200kg/drum

Commonly used packaging for component B is: 1 kg/bottle (if it is 1:1 addition type silica gel, the packaging of component B is 25 kg/drum, 200 kg/drum)

If you have no previous experience in mold opening, you can also log in to our website to view detailed video tutorials on silicone mold opening .

If you encounter other problems that cannot be solved, you can contact our online service staff or send an email to hyd@szrl.net

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544Keywords: