Purchase Hotline 15815593375

After-sales Hotline 15207551155

Free samples, free customized after-sales guarantee

Contact Us

Tel: 89948454 / 83212351

Fax: 0086-755-89948030

Q Q: 2355542596

Email: hyd@szrl.net

Address: building a, No. 3, Hongling 1st Road, Liulian Shibi Industrial Zone, Pingdi Town, Longgang District, Shenzhen

Non-deformable mold silicone

Category:

Number: 1375406498367819776

Product Description

Introduction of non-deformable mold silicone :

The reason why it is called non-deformable mold silicone means that the mold silicone has better tear resistance, tensile properties and shrinkage resistance, and the silicone mold made is durable and does not deform. Hongyejie's non-deformable mold silicone is mainly the HY-6 series of condensation type silicone and the HY-E series of addition type silicone. The hardness is 25-35 degrees, and the performance is in the best state. The mold silicone is composed of AB components, A component is a fluid liquid, B component is a curing agent (vulcanizing agent), the A component of the silica gel needs to be added after the B component can be cured, after mixing the two Rapid prototyping and simple operation.

Application fields of non-deformable mold silicone :

(1) A large number of molds used for architectural decoration and decoration products: such as Roman columns, cultural stones, plaster lines, background walls, door covers, GRC, cement, resin furniture, railings, ceilings, pedestals, fountains, fireplaces, Silicone mold making for wall decoration, planting utensils, European furniture, furniture decoration, cornice, background wall, mosaic, sandstone products, sandstone sculpture products;

(2) It can also be used in the production of silicone molds in the handicraft industry: such as resin handicrafts, polyresin handicrafts, reliefs, Buddha statues, wax casting, handmade soaps, stationery gifts, Christmas ornaments, sculptures, figures, etc.;

(3) or the reproduction of products used in other industries: such as tire molds, shoe molds, etc.;

(4) It can also be specially adjusted and produced according to customer product requirements.

Features of non-deformable mold silicone :

(1) Good fluidity, easy to defoaming, easy to pour, easy to operate and easy to demould;

(2) Good weather resistance, high and low temperature resistance, acid and alkali resistance, and aging resistance;

(3) High tensile and tear strength, low linear shrinkage (shrinkage rate of condensation type silicone ≤ 0.3%, shrinkage rate of addition type silicone ≤ 0.1%);

(4) There are many times of mold turning (for example, the reproduction times of gypsum products can reach more than 1,000 times);

(5) It is not limited by the thickness of the product, and can be quickly cured at room temperature;

(6) The hardness, viscosity, color, operating time, curing time, etc. of silica gel can be adjusted according to customer requirements.

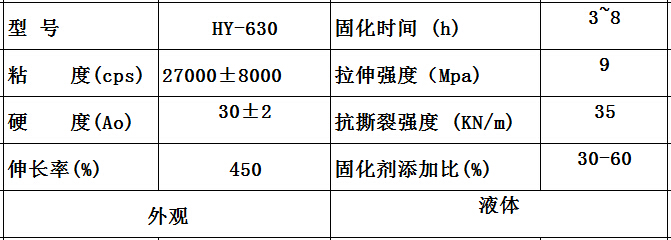

Hongye silicone - non-deformation mold silicone HY-630 parameters:

Remarks : The above parameters are only the parameters of this model HY-630, and the parameters of other models are not shown; if you have special requirements, please contact our company; after curing, the hardness, viscosity, and operating time can be specially adjusted and provided according to customer needs.

The operation method of non-deformation mold silicone material :

There are three ways to open the Roman column silicone mold: overmolding, rinsing, and perfusion. The production process of silicone mold is as follows:

1. Use a clean container to hold 500g of silica gel, add 5% curing agent at room temperature, and stir well.

2. Clean and polish the initial product mold with detergent.

3. The vicinity of the smooth initial mold is surrounded by wooden strips, and the wooden strips are also treated with detergent, and the open space in the center is preferably 2-4 cm.

4. Slowly pour the prepared liquid silica gel along a fixed pouring point, and vibrate from time to time to remove the air inside.

5. After the glue has cured completely in 60 minutes, surround it with wooden strips, leave a 4cm open space, and remove the log strips.

6. Pour the liquid plaster onto the plaster mold to make the plaster outer mold of the silicone mold.

7. Remove the wooden strips after 20 minutes, and the plaster mold is completed.

Precautions for non-deformable mold silicone :

1. The amount of curing agent should be determined according to the temperature, and it will be reduced when the temperature is high. If the curing agent is used too much, the mold will become hard and brittle; if the curing agent is used too little, the operation time will be prolonged.

2. In order to prevent the physical properties of silica gel from changing, it is recommended not to add silicone oil.

3. In order to achieve the best use effect of your mold, please store the mold for at least 24 hours before use. Tire molds are used to vulcanize various types of tires.

Hongye silicone conventional packaging:

Commonly used packaging of component A silicone is: 25kg/drum, 200kg/drum

The commonly used packaging of component B curing agent is: 1 kg/bottle

If you have no previous experience in mold opening, you can also log in to our website to view detailed video tutorials on silicone mold opening .

If you encounter other problems that cannot be solved, you can contact our online service staff or send an email to hyd@szrl.net

National Consulting Hotline: 189-8878-9544

National Consulting Hotline: 189-8878-9544Keywords: